News

Tungsten Price Surge Drives Innovation: RuiYi’s Carbide Products Lead Industry Trends

As a strategic and irreplaceable metal resource, tungsten has been witnessing a sustained price rally in 2026, reshaping the landscape of the global carbide industry. Backed by tight supply-demand dynamics and technological advancements, manufacturer RuiYi carbide blade is leveraging its expertise to optimize core products—including tungsten carbide blade, carbide scraper, carbide wear parts, carbide inserts, carbide snow plow blades, and tungsten carbide inserted plow blades—to navigate market changes and capture growth opportunities. This news blog delves into the latest tungsten material trends, carbide product price dynamics, and RuiYi’s competitive edge in the evolving market.

Tungsten Material Trends: Tight Supply and Technological Upgrade Lead the Way

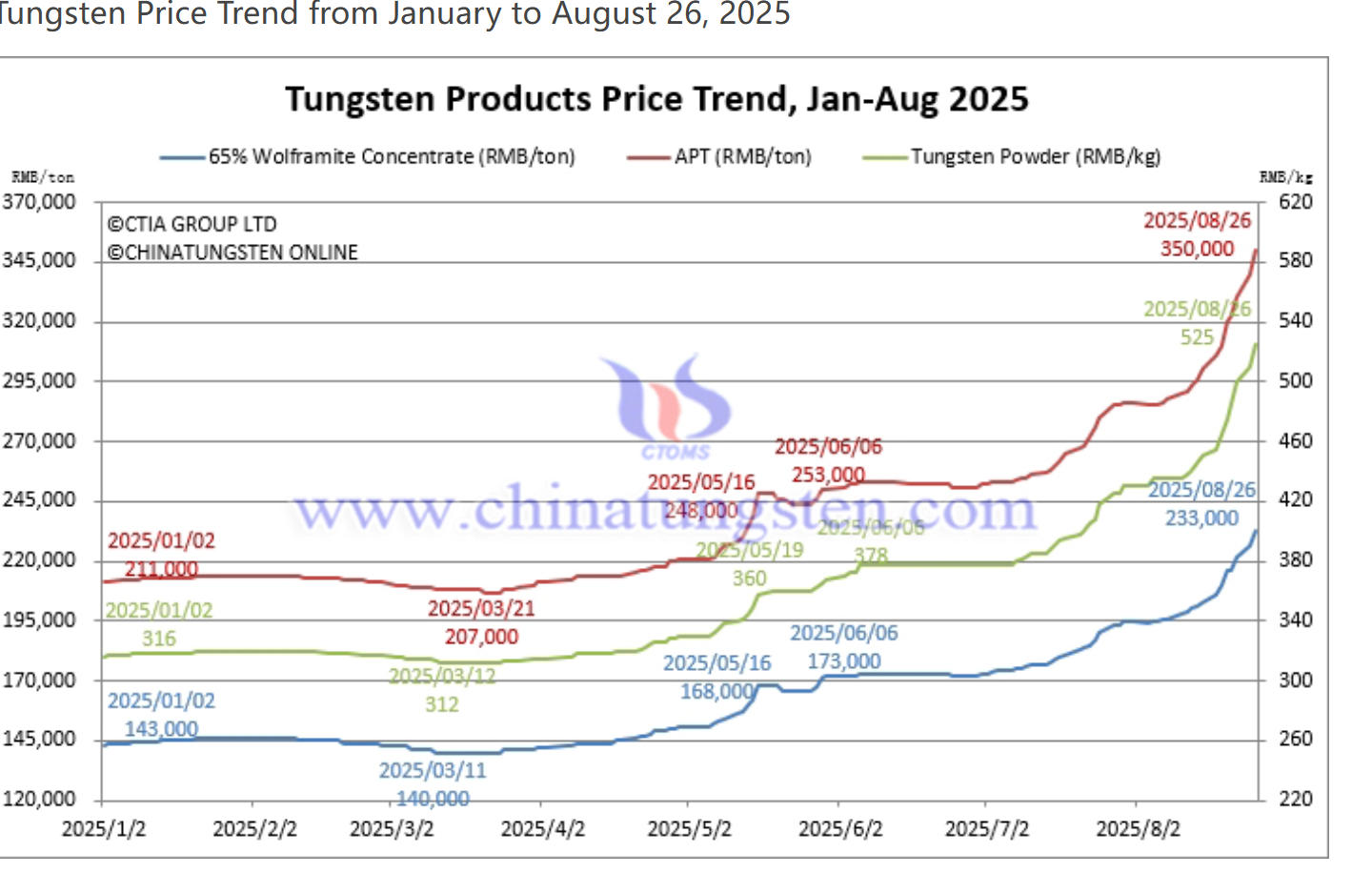

The global tungsten market has entered a phase of high-price operation since the start of 2026, with core products hitting record highs.

Data from China Tungsten Online shows that on January 21, the price of 65% black tungsten concentrate reached 528,000 RMB per standard ton, up 14.8% from the beginning of the year, while tungsten carbide powder surged by 15.4% to 1,200 RMB per kilogram

2. Industry analysts point out that this upward trend is driven by multiple factors: limited supply due to state-controlled mining quotas, rising demand from emerging industries, and depleted social inventories, creating a tight balance between supply and demand that is expected to persist throughout 2026

Beyond price fluctuations, technological innovation is reshaping tungsten carbide material development. The industry is shifting from traditional WC-Co matrices to high-performance alternatives, such as ultra-fine grain carbide with grain sizes refined to below 0.2μm—boosting hardness and wear resistance by over 30% while maintaining toughness

3. RuiYi has adopted this advanced technology, incorporating grain growth inhibitors like VC and Cr3C2 into its production process to enhance product durability. Additionally, non-cobalt binders (Fe-Ni based) are gaining traction as an eco-friendly and cost-effective solution, reducing production costs by 40% and carbon emissions by 60% without compromising performance

3. These material innovations are particularly critical for carbide wear parts and tungsten carbide inserted plow blades, which require extreme resistance to impact and abrasion.

Carbide Product Price Trends: Cost Pass-Through and Differentiated Pricing

The soaring tungsten prices have triggered a third round of price hikes in the carbide tool industry since November 2025, with an average increase of over 15% and cumulative annual gains expected to reach 50%-60% for CNC inserts <superscript>6. The price dynamics of RuiYi’s core products align with industry trends, while showing differentiation based on specifications, precision, and customization:

Standard products: Uncoated tungsten carbide blade and carbide inserts are priced between 180-450 RMB per kilogram for bulk purchases (>100kg), representing a 15%-20% increase from 2025

Coated versions (TiAlN/TiN) command a 40%-200% premium due to enhanced wear resistance

Customized parts: Carbide snow plow blades, tungsten carbide inserted plow blades, and precision carbide scraper for specialized industries (agriculture, construction) range from 800-1,500 RMB per kilogram, as their complex structures and high-precision grinding drive up production costs

Premium series: Ultra-fine grain carbide wear parts for aerospace and new energy sectors exceed 2,000 RMB per kilogram, leveraging advanced materials and coating technologies to meet strict performance requirements

RuiYi’s competitive pricing strategy—balancing premium raw materials and advanced manufacturing with affordability—has helped it retain market share amid the price surge. For bulk orders, the manufacturer offers flexible pricing to support long-term partnerships with distributors and industrial clients

RuiYi’s Product Portfolio: Tailored Solutions for Diverse Industries

Founded in 2006, as a trustedmanufacturer RuiYi carbide blade, specializing in ODM/OEM services for a full range of carbide products. Its offerings are designed to address the unique needs of agriculture, construction, machinery, and winter maintenance industries:

Agriculture & Construction

RuiYi’s tungsten carbide inserted plow blades adopt tungsten carbide welding technology to enhance wear resistance, making them suitable for hard soil and corn cultivation. These blades extend service life by 3-5 times compared to traditional steel alternatives, reducing replacement costs for farmers . T

he carbide wear parts for tillage machinery are engineered with gradient structures—hard surface layers and tough cores—to withstand heavy-impact operations.

Winter Maintenance & Industrial Cleaning

The carbide snow plow blades are built for extreme cold and abrasive conditions, withstanding temperatures as low as -40℃ while maintaining edge sharpness. For industrial applications, carbide scraper products feature precision-ground edges to remove stubborn residues from machinery, ensuring operational efficiency and reducing downtime.

Precision Machining

RuiYi’s carbide inserts—available in various grades and coatings—cater to CNC machining of high-hardness materials like titanium alloys and heat-resistant steels. The inserts integrate nano-multilayer coatings (TiAlN/CrN) to improve oxidation resistance and extend tool life by 2-3 times

RuiYi’s production strength lies in its advanced grinding machines, skilled engineering team, and strict quality control. By sourcing top-grade tungsten carbide raw materials and optimizing the powder metallurgy process, the manufacturer ensures consistent product performance—from edge sharpness to surface integrity

Outlook: Opportunities in Import Substitution and Emerging Sectors

The global carbide industry is witnessing accelerated import substitution, with domestic manufacturers like RuiYi gaining ground in the mid-to-high-end market. Currently, China’s CNC insert localization rate stands at around 50%, leaving ample room for growth.

As new energy vehicles and aerospace sectors expand, demand for high-precision carbide products is expected to grow at 15% annually, driving innovation in ultra-fine grain materials and composite coatings

For RuiYi, the focus will remain on technological R&D and customized solutions to capitalize on tungsten material trends and price dynamics. By aligning its product portfolio with industry upgrades, the manufacturer is well-positioned to become a leading global supplier of high-performance carbide products.